Why Your Next Pair of Work Gloves Should be Made with Material4X®

Leather gloves or synthetic leather gloves? The age old question that holds many of us wrench turners and DIYers up at the local hardware store. If you work with your hands, chances are you lean one way or the other and you've been buying the same pair for years. For decades, traditional leather gloves have been THE choice for heavy-duty work, and rightly so.

Leather is excellent when it comes to abrasion resistance. It has a high tensile strength; it becomes softer and more pliable with use, is resistant to heat, tearing, and punctures while staying warm in the winter and cool in the summer. Leather is definitely awesome, but it certainly has its disadvantages, and the evolution of synthetic materials gives working hands the best of both worlds. Cows, pigs and goats can breathe a sigh of relief in the name of material science!

HIDE AND FIBERS

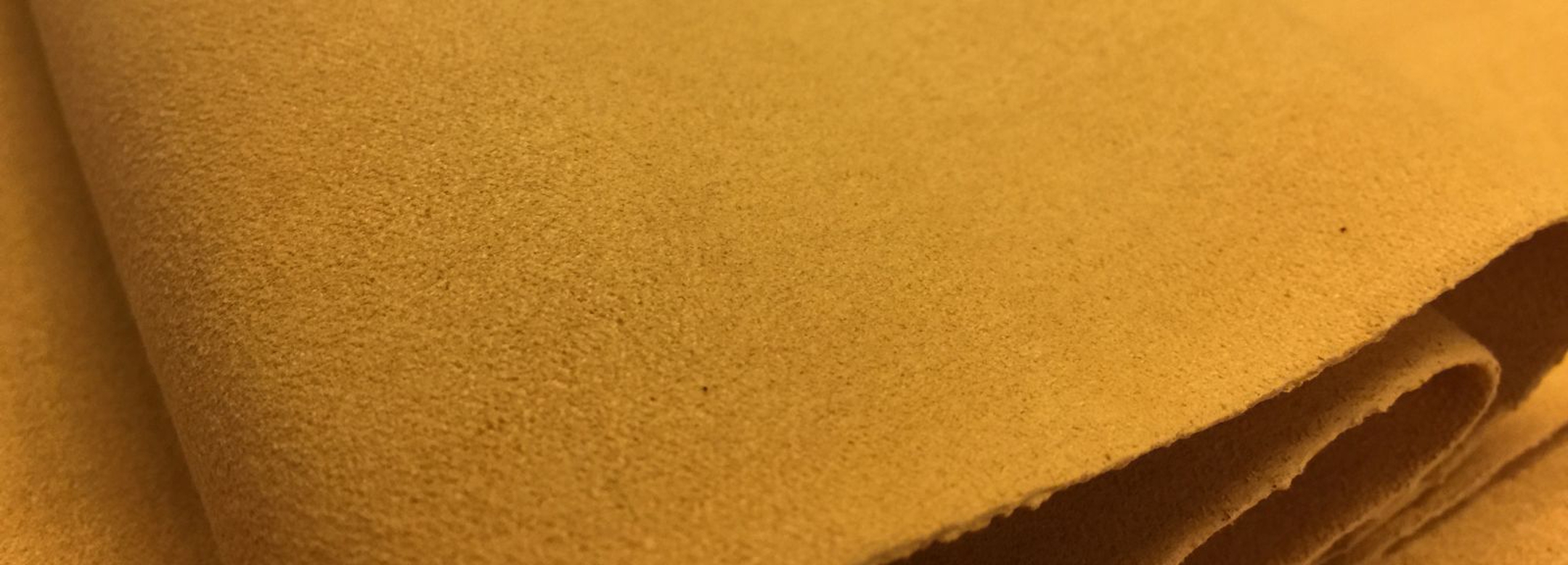

Even natural hide (in all of its glory) has limitations. I mean, we are talking about a completely natural product here, so there is a level of inconsistency with natural leather. The yield of the hide is limited to the size of the animal. It’s not always uniform in thickness; it can have holes and other imperfections that compromise quality and ultimately, the working performance of the product. When it comes to dexterity and tactility, leather work gloves are limited by the thickness of the hide i.e the dermis. For example, a thin and highly dexterous hide such as Hair Sheep is no match for cowhide on the jobsite, but it's ideal for law enforcement who require tactile control on patrol.

Natural Hide Detail

The introduction of ultra thin micro fibers allowed material makers to emulate the soft, supple feel of natural leather and eliminate certain "defects or inconsistencies" found in natural leather. The initial chemical materials are created, spun, cut, intertwined, needle punched, cleanser impregnated, coagulated, fiber extracted and finished with a buffing to create a man-made material more versatile than natural leather. Synthetic leather not only provides excellent abrasion resistance, tear resistance, and puncture resistance, it is also machine washable. When it comes to dirty jobs, synthetic leather does not harden or retain moisture when exposed to water, oils and chemicals unlike most natural leather work gloves. Synthetic material blends have given PPE makers more firepower to battle injuries in a multitude of hazardous working environments than ever before.

MATERIAL4X® MICROFIBER SUEDE

Natural hide and microfibers have coexisted for decades, and natural leather isn’t going to disappear anytime soon, but it’s the various man-made microfibers that are leading the performance PPE industry. From extreme abrasion resistance and cut resistance to functional heat resistance, it’s all about the material blend. The objective with Material4X was to develop an alternative to leather that provided consistent quality, higher abrasion resistance and improved dexterity, while still being pliable, soft to the touch and machine washable.

It was a tall task that required Mechanix Wear R&D to pursue a new material construction. Ian Batch, a material expert, further explains the unique construction of Material4X. “It started with a triple helix fiber. The triple helix has a strong core fiber wrapped with blended polyester and spandex fibers to achieve a full, soft hand feel.

Triple Helix Fiber by AX Suede™

After the triple helix fiber is woven, the material is stretched taut and heat set. This stretching and setting condenses the fiber to create a dense, yet thinner construction. This process gives Material4X® higher abrasion resistance, improved dexterity and greater tear resistance while remaining soft to the touch and machine washable.”

Material4X® Detail

So, why choose Material4X? It stacks up to the toughest natural leather yet it's softer, more dexterous and machine washable. It's the perfect leather alternative, and at 0.8mm thin, Material4X offers the best combination of durability and dexterity. This allows the user to have maximum control when handling smaller items while still providing extreme abrasion resistance. Its triple helix fiber construction allows Material4X to perform with abrasive materials such as concrete block, rough-cut wood, and steel. When compared to standard microfiber utility gloves, Material4X microfiber suede lasts up to four-times longer. That's durability redefined, one pair of gloves at a time.